CONDENSERS

Condensers are essentially the radiator of the air conditioning system. Their job is to condense the liquid refrigerant into a gas, dissipating that heat that this process creates through the fins of the condenser so that the engine cooling fan can safely blow that heat out into the atmosphere.

Essentially, there are three things that cause a condenser to go bad:

-

Age-related leaks from rotted tubes

-

Internal blockage

-

External blockage

Sometimes they leak refrigerant, but more often they go bad when the compressor tears apart and chunks of it end up inside the tiny tubes of the condenser. In either scenario, the condenser is not likely to be reparable. Fortunately, Acme Radiator has multsources for high-quality A/C condensers. We are also able to repair some of them — if they're leaking due to accident damage or some other outside cause.

However, it's rare that a condenser can be repaired. The condenser in the pictures on the left side (below) is the exception. The fins couldn't dissipate any heat because they were plugged solid with more than a half-million miles of road grime. As you can see in the bottom picture, we cleaned the aluminum condenser, saved the customer some money and he's back on the road, enjoying the cool air!

Air conditioning has a language all its own and oftentimes mechanics forget that their customers simply aren’t versed in it. Therefore, we’ve prepared this primer for you, so whether you come to us here at Acme Radiator in Islip Terrace, Long Island – or to someone else – you’ll at east understand the basics of what’s happening.

AIR CONDITIONING

EVAPORATORS

The evaporator is just like the condenser. Except that it's the exact opposite. Okay, so the condenser condenses the refrigerant, turning it into a liquid, and the evaporator makes that liquid evaporate into a gas... other than that, they're very similar! Both are (usually) made of very thin aluminum with aluminum fins between the tubes. Both convert liquid and gas refrigerant. Both can develop leaks. And both are available here at Acme Radiator! There is no better place on the Island to replace your evaporator.

OTHER COMPONENTS & REFRIGERANT

Acme Radiator's inventory doesn't stop at the main components. We also carry many smaller (but equally important) parts for te many types of air conditioning systems. Because we don't carry general auto parts, our parts are normally both better and less expensive than the ones you'll find at the local parts store! Some parts offered here at Acme include orifice tubes, accumulators, expansion valves, receiver/driers, hose assemblies, custom hoses. We also offer crimping services if you need us to build custom hoses!. We also HFC-1stock (and install) refrigerants, such as HFC-34a and R-1234yf,

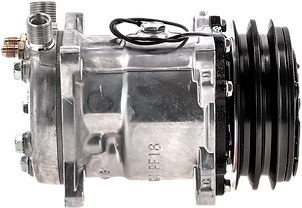

COMPRESSORS

The compressor is essentially the heart of the A/C system, much like your vehicle's engine. And just like the engine, the compressor has pistons that rotate on a shaft to force the rest of the system to do its job. Also like a motor, a compressor is prone to failure. And why not? Moving parts often go bad and, unlike the engine that controls power to your wheels, the oil in the compressor is never supposed to be changed, although there are times that it dries up and the next thing you know, parts of your compressor are spread out in chunks throughout your A/C system.

The ACCUMULATOR or RECEIVER/DRIER: An accumulator filters the refrigerant when it is in a gaseous state. A receiver/drier filters the refrigerant when it is in a liquid state. Most manufacturers converted from receiver/driers to accumulators in the 1970s and 1980s.

REFRIGERANT is more commonly (but incorrectly) known as “freon” and is the gas/liquid which passes through all the components in the A/C system and draws heat and moisture from the passenger compartment. Freon (R12) was used for over 50 years, but was found to be causing a hole in the Ozone layer of Earth’s atmosphere and while DuPont switched to “Suva” (HFC-134a), people continued to call all refrigerants “freon.”

Today, the majority of automakers are using HFO-1234yf refrigerant, a product co-developed by duPont and Honeywell, now being made in both China and the United States by Honeywell. 1234yf is a vast improvement over 134a in the area of ozone protection. Although Mercedes Benz once concluded that the product was flammable, further research proved that the conditions for 1234yf to ignite a fire were nearly impossible to replicate in the real world.

The ORFICE TUBE or THERMAL EXPANSION VALVE regulates the liquid refrigerant going into the bottom of the evaporator. It actually acts as a restrictor to the flow of the liquid refrigerant. CCOTs (Clutch Cycling Orifice Tubes) essentially replaced TX valves long ago.

CHARGE PORT / SCHRADER VALVE: Refrigerant is installed into the system through the low-pressure port. The high-side port serves to keep a check on the high-end pressure as the system is being serviced. Once the service is over, the Schrader valves serve no purpose until the next maintenance.

The COMPRESSOR CLUTCH engages

and disengages the compressor.

HOSE ASSEMBLY: A combination of rubber and steel or aluminum pipes through which the refrigerant passes between the other major components.

A CLUTCH CYCLING SWITCH regulates the operation of the compressor depending on system pressures or temperatures.

REFRIGERANT OIL lubricates the air conditioning system and prevents the compressor from grinding to a halt.

The CONTROL PANEL: is located inside the vehicle’s dash and it’s where you select the temperature, quantity, and location of air to come from the heater / air conditioning system. On many newer systems, particularly on high-end vehicles, this comes in the form of Automatic Temperature Control (ATC), where the people in the car select a temperature and the vehicle maintains it.

A/C Service Terms:

Evacuate- Pull a vacuum on the system. This removes air from the system. Air has moisture and takes up space that refrigerant should be occupying. Putting refrigerant into a system without pulling out the air first will cause high pressures and poor (if any) cooling.

Recharge- Injecting refrigerant into a previously evacuated A/C system. Refrigerant can be put into the high-pressure side as a liquid prior to starting the engine and engaging compressor. After the engine is running, it must be put in thru the low-pressure side slowly. Always measure how much you have put in.

Recover- Taking the refrigerant out of the system and putting it into a can to filter out the impurities and using it over again. Refrigerant should never be discharged into the atmosphere.